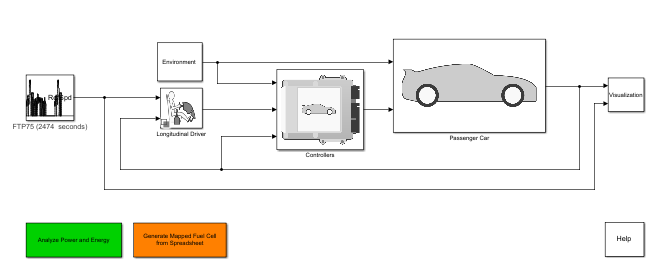

Build Fuel Cell Electric Vehicle

To design an energy system for a hydrogen-based vehicle, use the fuel cell reference application project with a high-fidelity fuel cell model in Simscape™. You can switch between a detailed and a mapped fuel cell. Use these models for design tradeoff analysis and component sizing, control parameter optimization, and hardware-in-the-loop (HIL) testing.

To create and open a working copy of the reference application project, see FCEV Reference Application or use this command.

openExample("autoblks/FCEVRefApplicationExample")

This table describes the blocks and subsystems in the reference application, indicating which subsystems contain variants. To implement the model variants, the reference application uses variant subsystems.

| Reference Application Element | Description | Variants |

|---|---|---|

Analyze Power and Energy | Double-click Analyze Power and Energy to open a live script. Run the script to evaluate and report power and energy consumption at the component- and system-level. For more information about the live script, see Analyze Power and Energy. | NA |

Generate Mapped Fuel Cell from Spreadsheet | Use the Model-Based Calibration Toolbox™ to create a mapped fuel cell model from measured fuel cell performance data stored in a spreadsheet. For more information, see Generate Mapped Fuel Cell from Spreadsheet. | NA |

Drive Cycle Source block — FTP75 (2474 seconds) | Generates a standard or user-specified drive cycle velocity versus time profile. Block output is the selected or specified vehicle longitudinal speed. | ✓ |

Environment subsystem | Creates environment variables, including road grade, wind velocity, and atmospheric temperature and pressure. | |

Longitudinal Driver subsystem |

Uses the Longitudinal Driver or Open Loop variant to generate normalized acceleration and braking commands.

| ✓ |

Controllers subsystem | Implements a powertrain control module (PCM) with regenerative braking, motor torque arbitration and power management. | ✓ |

Passenger Car subsystem | Implements a passenger car that contains an electric plant and drivetrain subsystems. | ✓ |

Visualization subsystem | Displays vehicle-level performance, battery state of charge (SOC), and equivalent fuel economy results that are useful for powertrain matching and component selection analysis. |

Evaluate and Report Power and Energy

Double-click Analyze Power and Energy to open a live script. Run the script to evaluate and report power and energy consumption at the component- and system-level.

The script provides:

An overall energy summary that you can export to an Excel® spreadsheet.

Electric plant and drivetrain plant efficiencies.

Data logging so that you can use the Simulation Data Inspector to analyze the powertrain efficiency and energy transfer signals.

For more information about the live script, see Analyze Power and Energy.

Drive Cycle Source

The Drive Cycle Source block generates a target vehicle velocity for a

selected or specified drive cycle. The reference application has these options.

| Timing | Variant | Description |

|---|---|---|

Output sample time |

| Continuous operator commands |

| Discrete operator commands |

Longitudinal Driver

The Longitudinal Driver subsystem generates normalized acceleration and

braking commands. The reference application has these variants.

Block Variants | Description | ||

|---|---|---|---|

Longitudinal Driver (default) | Control |

| PI control with tracking windup and feed-forward gains that are a function of vehicle velocity. |

| Optimal single-point preview (look ahead) control. | ||

| Proportional-integral (PI) control with tracking windup and feed-forward gains. | ||

Low-pass filter (LPF) |

| Use an LPF on target velocity error for smoother driving. | |

| Do not use a filter on velocity error. | ||

Shift |

| Stateflow® chart models reverse, neutral, and drive gear shift scheduling. | |

| Input gear, vehicle state, and velocity feedback generates acceleration and braking commands to track forward and reverse vehicle motion. | ||

| No transmission. | ||

| Stateflow chart models reverse, neutral, park, and N-speed gear shift scheduling. | ||

Open Loop | Open-loop control subsystem. In the subsystem, you can configure the acceleration, deceleration, gear, and clutch commands with constant or signal-based inputs. | ||

Controllers

To determine the motor torque and brake pressure commands, the reference application implements a supervisory controller. Specifically, the controller subsystem includes a powertrain control module (PCM) with:

Regenerative braking control

Motor torque arbitration and power management

Converts the driver accelerator pedal signal to a torque request.

Converts the driver brake pedal signal to a brake pressure request. The algorithm multiplies the brake pedal signal by a maximum brake pressure.

Implements a regenerative braking algorithm for the traction motor to recover the maximum amount of kinetic energy from the vehicle.

Implements a virtual battery management system. The algorithm outputs the dynamic discharge and charge power limits as functions of battery state of charge (SOC).

Implements a power management algorithm that ensures the battery dynamic discharge and charge power limits are not exceeded.

Regen Braking Control has these variants.

| Controller | Variant | Description |

|---|---|---|

Regen Braking Control | Series Regen Brake

(default) | Friction braking provides the torque not supplied by regenerative motor braking. |

Parallel Regen Braking | Friction braking and regenerative motor braking independently provide the torque. |

Passenger Car

To implement a passenger car, the Passenger Car subsystem

contains a drivetrain and electric plant subsystem. The reference application has

these variants.

Drivetrain

| Drivetrain Subsystem | Variant | Description | |

|---|---|---|---|

Differential and Compliance | All

Wheel Drive | Configure drivetrain for all wheel, front wheel, or rear wheel drive. For the all wheel drive variant, you can configure the type of coupling torque. | |

Front Wheel Drive

(default) | |||

Rear Wheel Drive | |||

Vehicle | Vehicle Body 3 DOF

Longitudinal | Configured for 3 degrees of freedom | |

Wheels and Brakes |

| For the wheels, you can configure the type of:

For performance and clarity, to determine the longitudinal force of each wheel, the variants implement the Longitudinal Wheel block. To determine the total longitudinal force of all wheels acting on the axle, the variants use a scale factor to multiply the force of one wheel by the number of wheels on the axle. By using this approach to calculate the total force, the variants assume equal tire slip and loading at the front and rear axles, which is common for longitudinal powertrain studies. If this is not the case, for example when friction or loads differ on the left and right sides of the axles, use unique Longitudinal Wheel blocks to calculate independent forces. However, using unique blocks to model each wheel increases model complexity and computational cost. | |

| |||

Electric Plant

| Electric Plant Subsystem | Variant | Description |

|---|---|---|

| Battery |

| Configured with electric battery |

| Motor |

| Mapped motor with implicit controller |

| Interior permanent magnet synchronous motor (PMSM) with controller |

See Also

Interior PMSM | Interior PM Controller | Datasheet Battery | Drive Cycle Source | Longitudinal Driver | Mapped Motor