Configuring Angle-Dependent Behavior in the Angle-Based Rotational Domain

This example shows how to set up a a custom mechanism with characteristics that depend on the instantaneous angle in an angle-based rotational network.

Key modeling steps in this example include:

Using a Rotational Motion Sensor (AB) block to measure the angle of a point in the system.

Using a PS Lookup Table to calculate a characteristic based on the angle.

Adjusting a block's behavior using the output from the PS Lookup Table.

In this example, a brake disc has a low spot over an 80-degree angle. When this low spot moves through the brake calipers, the normal force applied by the calipers on the brake disc decreases, leading to slower vehicle stopping compared to a brake disc with a uniform surface.

System Overview

Open the ConfiguringAngleDependentBrakeIrregularity model.

open_system('ConfiguringAngleDependentBrakeIrregularity');

This system models a vehicle brake that consisting of a disc passing through calipers. An angle-based rotational network models the rotating brake disc and friction torque. The disc is modeled using an Inertia block, while a Rotational Motion Sensor block measures the disc's angle. The Disc Surface Condition subsystem adjusts the disc's axial length based on its angle. When the disc's low spot passes through the caliper contact area, the axial length is reduced. The two Rotational World blocks represent separate stationary points along the axis that have angles of 0 degrees: Rotational World1 is a reference point for the Rotational Initial Spacer and Rotational World2 represents the nonrotating brake pad.

A position-based translational network models the translation of the calipers and plates, as well as the disc's axial thickness. A caliper actuator controls the axial position of the caliper pad that clamps the brake disc. A Force Sensor block measures the force between the caliper and disc.

The force measured by the Force Sensor block serves as the normal force input signal to the Rotational Friction block in the rotational network. When the disc's axial length is reduced due to the low spot, the normal force- and thus the frictional torque- decreases.

The rotational network includes a Wheel and Axle block that connects to a second position-based translational network. This translational network models the vehicle's forward motion and includes a 500 kg mass, representing one-quarter of a passenger vehicle's mass. A Translational Motion Sensor block measures the vehicle's velocity and position.

In this scenario, the vehicle starts with a velocity of 50 km/hr, and the disc has an initial angle of -90 degrees. The caliper actuator begins clamping the brake disc after 1 second, causing the vehicle to decelerate.

Custom Mechanism

The brake disc typically has an axial length of 10 mm, but it has a low spot with an axial length of 7.5 mm. As the brake disc rotates, this low spot moves through the caliper contact area, which does not rotate and spans -30 degrees to 30 degrees. The low spot covers an 80-degree angular span. This table highlights four key positions of the low spot on the disc as it aligns with the caliper contact area.

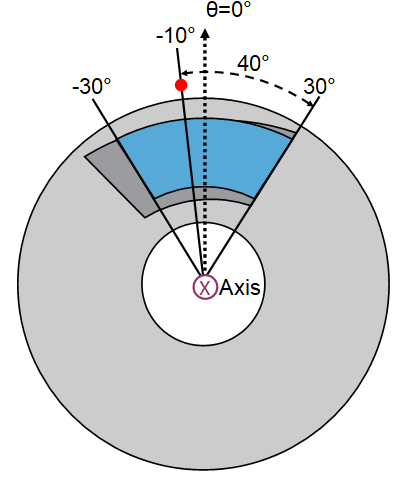

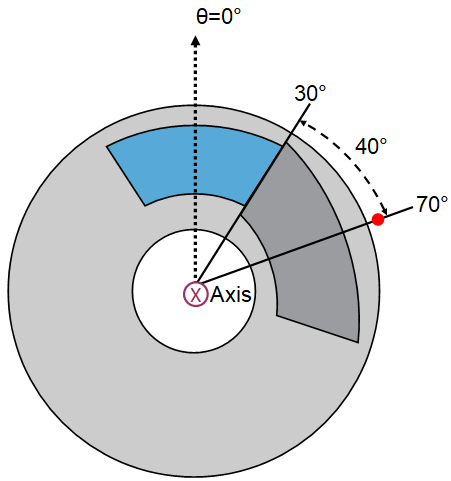

Disc Angle (deg) | Disc-Caliper State | Physical View |

-70 | Low spot starts to pass through the caliper contact area. |

|

-10 | Low spot first spans the entire caliper contact area. |

|

10 | Low spot stops spanning the entire caliper contact area. |

|

70 | Low spot has completely passed through the caliper contact area. |

|

View the model of the varying disc axial length.

open_system('ConfiguringAngleDependentBrakeIrregularity/Disc Surface Condition/Nonuniform');

The input signal, A, represents the disc angle, while the output signal, L, is the disc axial length. The model includes a PS Lookup Table and a PS Transfer Function. The PS Lookup labeled Table, labeled "Angle-Dependent Length", outputs the disc's axial length as function of the disc angle. to capture all key regions, it is convenient to define the brake disc angles from -90 to 270 degrees, as shown in the Disc-Caliper States table. The Table grid vector parameter spans this range. The Rotational Motion Sensor block, which feeds into input signal A, wraps the sensed angle at -90 degrees, ensuring A always stays between -90 and 270 degrees. Consequently, the PS Lookup Table Extrapolation method does not affect the results.

The Table values in the PS Lookup Table are set so that the axial length linearly decreases as the disc angle increases from -70 to -10 degrees, reflecting the low spot's expansion to the entire caliper contact area. Then, the Table values have the axial length linearly increase as the disc angle increases from 10 to 70 degrees. The axial length reaches its maximum value when the brake disc angle is between 70 to 270 degrees and -90 to -70 degrees. The PS Transfer Function adds a degree of freedom between the disc angle and the disc's axial length, helping the numerical solver achieve more efficient computations.

Configuring the Networks

View the ConfiguringAngleDependentBrakeIrregularity model.

open_system('ConfiguringAngleDependentBrakeIrregularity');

The model includes an angle-based rotational network and two position-based translational networks. In the rotational network, the side view shows the axis pointing from left to right, while the front view shows the axis pointing into the page. Following the right-hand rule, positive angles, theta, logged for each angle-based rotational node, indicate clockwise rotation in the front view. In the physical view, a red circle marks a reference point on the brake disc, and a dashed vertical line represents the theta = 0 direction. When the reference point aligns with the theta = 0 line, the brake disc is at an angle of 0 degrees. For more details on setting directions in the angle-based rotational network, refer to the Interpreting Angle in the Angle-Based Rotational Domain example.

Both translational networks have positive directions that pointing from left to right, meaning that positive x and v values at each node in the translational networks indicate movement to the right.

Simulate the System and View Results from Scopes

Simulate the model with the disc plate low spot.

set_param([bdroot '/Disc Surface Condition'], 'SurfaceType', 'Nonuniform') open_system('ConfiguringAngleDependentBrakeIrregularity/Scope'); sim('ConfiguringAngleDependentBrakeIrregularity');

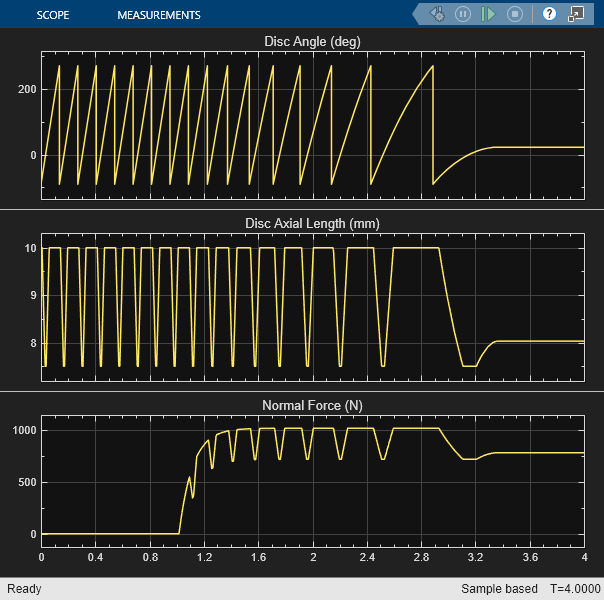

The disc starts with an initial angle of -90 degrees. During each revolution, the axial length of the disc in the caliper contact area varies between 7.5 mm and 10 mm because of the low spot on the plate. The caliper actuator begins clamping the disc plate after 1 second. The normal force exerted on the disc rises to a peak of just over 1000 N. When the low spot enters caliper contact area, the normal force decreases to 720 N.

Compare the Performance of the Nonuniform and Uniform Disc Surfaces

The Disc Surface Condition subsystem is a variant subsystem. You can use its dialog box to switch the disc surface between two options: a nonuniform plate with a low spot and a uniform plate with a constant axial length.

Simulate the system with the nonuniform and uniform plates to evaluate their performance. Plot the vehicle's position and velocity over time for each plate condition to compare their effects on vehicle stopping performance.

close_system('ConfiguringAngleDependentBrakeIrregularity/Scope'); set_param('ConfiguringAngleDependentBrakeIrregularity/Disc Surface Condition', 'SurfaceType', 'Nonuniform') outNonuniform = sim('ConfiguringAngleDependentBrakeIrregularity'); set_param('ConfiguringAngleDependentBrakeIrregularity/Disc Surface Condition', 'SurfaceType', 'Uniform') outUniform = sim('ConfiguringAngleDependentBrakeIrregularity'); figure; tiledlayout(2,1); nexttile; hold on plot(outNonuniform.tout, outNonuniform.yout(:,1)); plot(outUniform.tout, outUniform.yout(:,1)); title('Vehicle Position versus Time'); ylabel('Position (m)'); legend('Nonuniform Disc Surface', 'Uniform Disc Surface') nexttile; hold on plot(outNonuniform.tout, outNonuniform.yout(:,2)); plot(outUniform.tout, outUniform.yout(:,2)); title('Vehicle Velocity versus Time'); ylabel('Velocity (km/hr)');

The brake system with a uniform disc surface enables the vehicle to stop within 15.5 meters, taking 2.2 seconds after the caliper actuator is engaged at a time of 1 second. In contrast, the brake system with a nonuniform disc surface results in the vehicle stopping within 16.9 meters, taking 2.4 seconds after the caliper actuator is engaged. This change represents a 9% increase in both stopping distance and stopping time due to the disc surface irregularity.