Develop and Implement Field-Oriented Control for Motor Drives in Simulink

Overview

In this webinar you will learn how to quickly develop and adapt motor control algorithms with the reference examples from Motor Control Blockset. The models provided allow you to verify the algorithms unsing simulation and generate compact and efficient code for a microcontroller. You can implement an automated workflow that updates based on motor parameter inputs, eliminating the need for redeployment. In this session a MathWorks engineer will walk through this workflow for a permanent magnet synchronous motor (PMSM).

Highlights

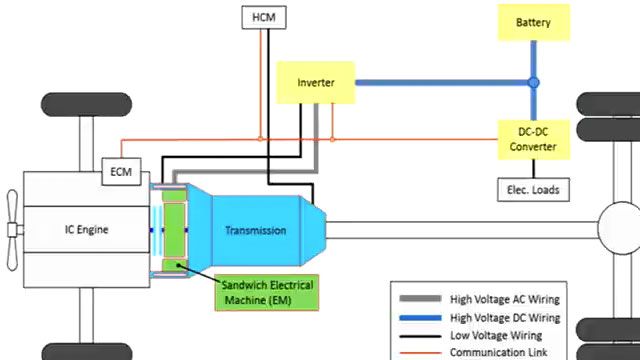

- Model motor and inverter dynamics at different levels of fidelity

- Parameterize a PMSM model

- Design a field-oriented controller, compute gains and verify through closed-loop simulations

- Deployment through automatic code generation

- Validate algorithms for different motors without redeployment

About the Presenter

Eva Pelster is a senior application engineer at MathWorks. She holds degree in Aerospace Engineering from the University of Stuttgart. Her area of expertise is Model-Based Design and Simscape for modelling physical systems. Before joining MathWorks, she worked in a technical consulting company.

Recorded: 16 May 2024