Models Exchange and Virtual Integration with MATLAB and Simulink

Giacomo Gentile, Collins Aerospace Applied Research and Technology

Alessandro Mignogna, Collins Aerospace Applied Research and Technology

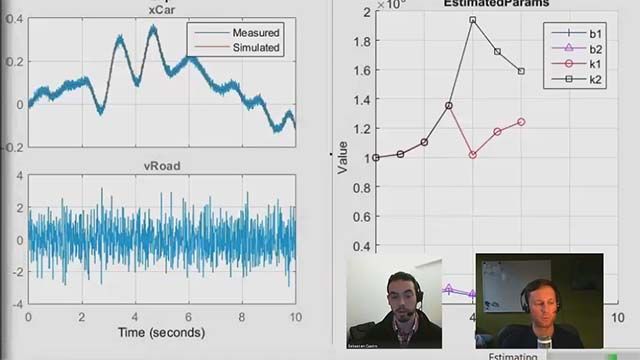

See how Collins Aerospace Applied Research and Technology used Simulink® and the FMI standard to facilitate the internal collaboration between Collins Aerospace teams and streamline external collaboration between OEM and Collins product owners. You’ll see a comparison of the ability to export and import standalone FMUs with the coupling approach of the tools identifying difficulties and benefits. You’ll also explore multiple industrial and research use cases focusing on system and software validation and verification in a virtual environment, including exporting Simulink models towards different external simulation ecosystems and importing third parties’ virtual test benches in Simulink.

Published: 30 May 2022