Implementing Field-Oriented Control for a Motor on an FPGA

Overview

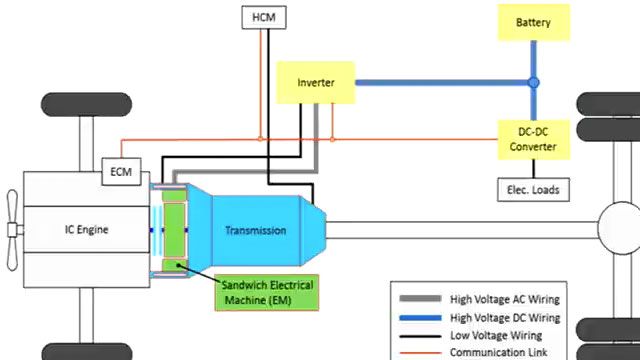

Engineers are developing high frequency switching power electronics and motor control systems driven by complex algorithms. To implement such algorithms, engineers are considering FPGA/System on Chip (SoC) devices.

In this session you will learn how to deploy motor control algorithms on Xilinx Zynq UltraScale+ MPSoC module from the Trenz Electronic motor development kit with minimal FPGA programming knowledge. Using a field-oriented control (FOC) algorithm as an example, we will demonstrate HDL code generation for the FPGA fabric of the development kit to drive a permanent magnet synchronous motor (PMSM).

Highlights

- Simulate Field Oriented Control (FOC) algorithm for PMSM.

- Partition the control algorithm in the model between the processor and FPGA.

- Generate optimized C & HDL code from the Simulink model for the Xilinx Zynq UltraScale+ MPSoC module.

- Automatically deploy the code to both the processor and FPGA.

About the Presenter

Swathy Pillai is a Product Manager at MathWorks focusing on Motor Control Blockset. She holds a master’s degree in Electrical Engineering with specialization in Power Electronics & Drives and has over 5 years of experience in Model-Based Design related to power electronics and motor control. Before MathWorks, she worked with L&T Electrical & Automation, Schneider Electric India in R&D division where she was involved in control algorithm development and coding for Low and Medium Voltage industrial drives and other power electronic converters.

Recorded: 19 Oct 2022