Enabling the Green Hydrogen Supply Chain with MATLAB and Simulink

Production of green hydrogen relies upon conversion of photovoltaic (sun) and/or eolic (wind) energy into hydrogen gas through electrolysis. This brings multidisciplinary challenges (concept design, planning, operation, maintenance) to guarantee satisfactory return of investment. Now learn how multidomain simulation empowers integration with grid and energy storage, power electronic design, and techno-economic studies.

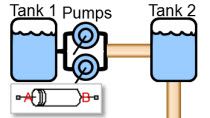

Once produced, hydrogen must be compressed and transferred from tanks to fuel cells. Electricity is then regenerated for electric propulsion in ships, trucks, or busses. But how can hydrogen, an extremely sensitive gas, be handled safely at all stages? Model-Based Design provides a solid foundation for this. In this session, you will see how safe valve and cooling controls are modeled with Simulink®.

Finally, it may be that your company is responsible for system integration. Hydrogen-based fuel cells are acquired and integrated in a complex multidomain system and co-exist with other energy entities (e.g., battery, diesel generator). How can you maximize the return for all assets? Can testing be enabled by desktop models used early in the development cycle? Join us to find out how the MathWorks toolchain makes it possible.

Published: 29 May 2022