From PID Control to Adaptive Control: Systematically Designing Controllers in Simulink

Overview

While PID control continues to be ubiquitous, other control techniques such as adaptive control and learning-based control are gaining more acceptance. In this session, MathWorks engineers will walk you through how you can use systematic and automated ways to quickly design and implement different types of controllers, ranging from PID controllers to model reference adaptive controllers.

Highlights

Through demonstrations, you will learn how to:

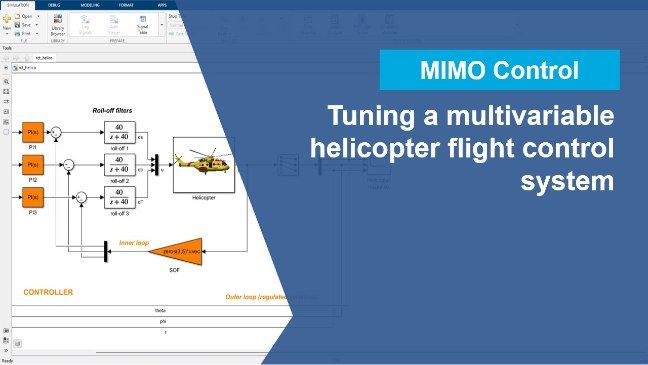

- Automatically tune PID controllers for SISO, MIMO, and gain scheduled control systems.

- Generate code to automatically tune PID controllers on hardware such as Speedgoat target computers or Texas Instruments C2000 microcontrollers

- Implement model-free adaptive control techniques such as extremum seeking and model reference adaptive control for systems with unknown or changing plant dynamics and disturbances.

About the Presenter

Siddharth Jawahar is a Product Manager for MathWorks with a focus on Control System Toolbox, Simulink Control Design, and Robust Control Toolbox. Before MathWorks, he graduated from the Georgia Institute of Technology in 2017 with a Master’s Degree in Electrical Engineering.

Recorded: 17 Feb 2022